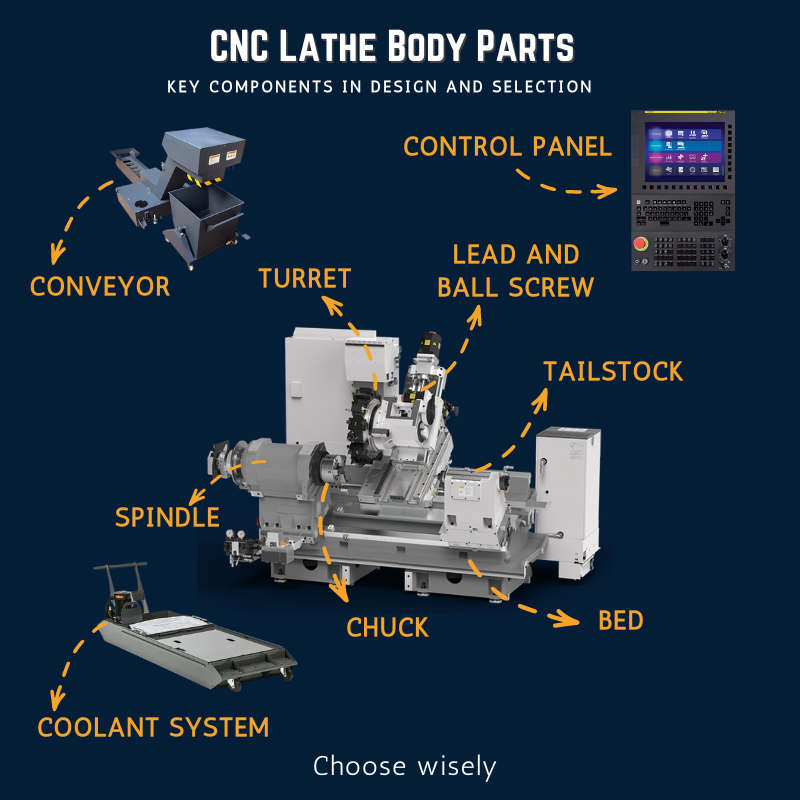

If you're involved in CNC machining, the base or foundation of your machine is important for optimal performance. The base of a CNC machine is a critical component that ensures stability and precision during machining operations. It supports the entire structure, absorbs vibrations, and maintains alignment. Common materials include cast iron, steel, and epoxy granite, each offering distinct advantages for different applications.

Choosing the right CNC machine base can significantly impact the quality and accuracy of your machining projects. Understanding the options and their benefits is key to making an informed decision.

Types of CNC Machine Bases

The foundation of a CNC machine directly affects its performance and longevity. Different materials and designs cater to various machining requirements, ensuring stability and precision. Here are the primary types of CNC machine bases:

- Cast Iron Bases

Cast iron is a popular choice for CNC machine bases due to its excellent damping properties, which help reduce vibrations during machining. This material is highly durable and provides a solid, stable foundation. The weight and density of cast iron provide a sturdy foundation, ensuring that the machine remains stable even during heavy-duty operations. However, the heft of cast iron can be a drawback, making installation and transportation more complex. Additionally, the cost of cast iron can be higher, but its durability often justifies the investment.

- Steel Bases

Steel bases are known for their strength and rigidity. They are lighter than cast iron, making them easier to move and install. Steel bases are also less prone to cracking, offering a longer lifespan. Steel bases offer a balance between strength and weight. They are more manageable compared to cast iron, making them suitable for workshops that require frequent reconfiguration of machinery. The rigidity of steel ensures that the CNC machine remains aligned, which is important for precision work. However, steel does not have the same level of vibration damping as cast iron, which might affect the quality of high-precision tasks. To counteract this, some steel bases are designed with additional vibration damping mechanisms.

- Epoxy Granite Bases

Epoxy granite is a composite material made from granite aggregates and epoxy resin. It offers excellent vibration damping and thermal stability, making it ideal for high-precision machining. Epoxy granite bases are also resistant to corrosion and are lighter than cast iron. Epoxy granite bases are engineered to provide superior vibration damping and thermal stability. The lighter weight of epoxy granite compared to cast iron makes it easier to handle while still offering significant stability. Additionally, the resistance to corrosion ensures that the base remains in good condition over time, even in environments where moisture or chemicals are present.

Selecting the right CNC machine base is a foundational decision that influences the overall performance and accuracy of your machining operations. By understanding the properties and benefits of different materials, you can make an informed choice that best suits your specific needs and projects.

Should You Mount Your CNC Machine Base on the Ground or Not?

When setting up a CNC machine, one of the critical decisions is whether to mount the base directly on the ground or use an elevated platform or isolation system. Both approaches have their own sets of advantages and disadvantages, which can impact the machine's performance, stability, and maintenance.

Ground Mounting

Mounting the CNC machine base directly on the ground is a common practice, especially in industrial settings. This method offers several benefits:

- Stability: Direct ground mounting provides a stable and solid foundation. The weight of the machine is evenly distributed, reducing the risk of tilting or misalignment.

- Vibration Control: A concrete floor can absorb and dampen vibrations effectively, which isimportantfor maintaining precision during machining operations.

- Cost-Effective: Ground mounting is often more cost-effective since it eliminates the need for additional platforms or isolation systems.

However, there are also some drawbacks to ground mounting:

- Leveling: Ensuring the floor is perfectly level is essential, as any unevenness can lead to inaccuracies in machining.

- Accessibility: Ground-mounted machines can be harder to access for maintenance and cleaning, especially in tight spaces.

- Floor Integrity: The floor must be robust enough to support the machine's weight without cracking or shifting.

Elevated Platforms and Isolation Systems

Alternatively, mounting the CNC machine on an elevated platform or using isolation systems can offer additional benefits:

- Vibration Isolation: Isolation pads or platforms can further reduce vibrations, enhancing precision, especially for high-precision or high-speed machining.

- Flexibility: Elevated platforms can make it easier to relocate the machine if needed. This is beneficial for workshops that frequently reconfigure their layout.

- Accessibility: Machines mounted on platforms can be more accessible for maintenance, adjustments, and cleaning.

- Thermal Isolation: Platforms can provide some degree of thermal isolation, protecting the machine from floor temperature fluctuations that could affect precision.

The drawbacks include:

- Cost: Elevated platforms and isolation systems can add to the initial setup cost.

- Complex Installation: Setting up an elevated platform requires careful planning to ensure stability and alignment.

- Space: Platforms can take up more vertical space, which may be a consideration in workshops with low ceilings.

The decision to mount your CNC machine base on the ground or an elevated platform depends on various factors, including the type of work you do, your workspace configuration, and budget. Each method has its benefits and challenges, so carefully consider your specific needs to make the best choice for your setup. A stable and well-supported CNC machine is essential for achieving high precision and long-term reliability in your machining projects.

Common Mistakes Buyers Make Regarding CNC Machine Bases

Here are some common mistakes buyers make regarding CNC machine bases and how to avoid them:

- Underestimating the Importance of the Base

Many buyers focus on the more glamorous specifications of CNC machines, such as spindle speed or software capabilities, while underestimating the significance of the base. The base is fundamental to the machine's overall performance, affecting stability, vibration damping, and accuracy.

Tips:

- Understand the Role of the Base: Recognize that a sturdy base is essential for maintaining precision and ensuring the longevity of the machine.

- Prioritize Base Quality: Give equal importance to the base material and design as you would to other specifications.

- Choosing the Wrong Base Material

The material of the CNC machine base significantly impacts its performance. Common materials include cast iron, steel, and epoxy granite, each with distinct advantages and disadvantages. Buyers often select a base material without fully understanding its properties and suitability for their specific applications.

Tips:

- Match Material to Needs: Select a base material that aligns with your machining requirements (e.g., cast iron for heavy-duty applications, epoxy granite for precision work).

- Research Material Properties: Study the damping properties, thermal stability, and durability of different materials before making a decision.

- Ignoring Vibration Damping Needs

Vibration can significantly affect the quality of the machining process. Buyers sometimes neglect to consider how well the base can absorb and dampen vibrations, leading to issues with precision and surface finish.

Tips:

- Evaluate Damping Capabilities: Choose a base material with good vibration damping properties, such as cast iron or epoxy granite.

- Consider Additional Isolation: In high-precision environments, consider adding vibration isolation pads or mounts.

- Overlooking the Installation Environment

The environment in which the CNC machine is installed can affect the performance of the base. Factors such as floor level, structural integrity, and environmental conditions are often overlooked.

Tips:

- Assess Installation Site: Ensure the floor is level, strong enough to support the machine's weight, and free from excessive vibrations.

- Control Environment: Maintain a controlled environment with stable temperatures and humidity levels to minimize thermal expansion and contraction.

- Failing to Plan for Future Upgrades

Some buyers do not consider the potential for future upgrades or changes in their machining needs. A base that is sufficient today might not support future enhancements or increased workloads.

Tips:

- Future-Proof Your Purchase: Select a base that can accommodate potential upgrades or expansions in your machining operations.

- Think Long-Term: Consider the longevity and adaptability of the base material and design.

- Neglecting Maintenance Requirements

Maintenance is critical for the longevity and performance of the CNC machine base. Buyers often overlook the maintenance needs of different base materials, leading to premature wear and performance issues.

Tips:

- Establish a Maintenance Schedule: Regularly inspect and maintain the base to ensure it remains in optimal condition.

- Choose Low-Maintenance Materials: Some materials, like epoxy granite, are less prone to corrosion and require less maintenance than others like steel.

- Ignoring Manufacturer Recommendations

Manufacturers provide specific recommendations for the installation and maintenance of CNC machine bases. Ignoring these guidelines can lead to improper setup and reduced performance.

Tips:

- Follow Manufacturer Guidelines: Adhere to the installation and maintenance instructions provided by the manufacturer.

- Consult with Experts: If in doubt, seek advice from experts or the manufacturer to ensure proper setup and maintenance.

The base of a CNC machine is an important factor that directly impacts its stability, precision, and overall performance. By avoiding these common mistakes and carefully considering the material, installation environment, vibration damping needs, and future requirements, you can make a well-informed decision that enhances the efficiency and accuracy of your CNC machining operations. Proper attention to the base will ensure that your investment delivers the best possible results and stands the test of time.