If you're considering buying a CNC machine, deciding whether to include automation can be overwhelming. Incorporating automation in your CNC machine purchase can significantly enhance productivity, reduce manual labor, and improve precision. However, it also involves higher initial costs and requires technical know-how. Evaluating your specific needs and resources is essential in making the right choice.

Automation can be a game-changer, but is it the right fit for your CNC setup?

Understanding CNC Automation

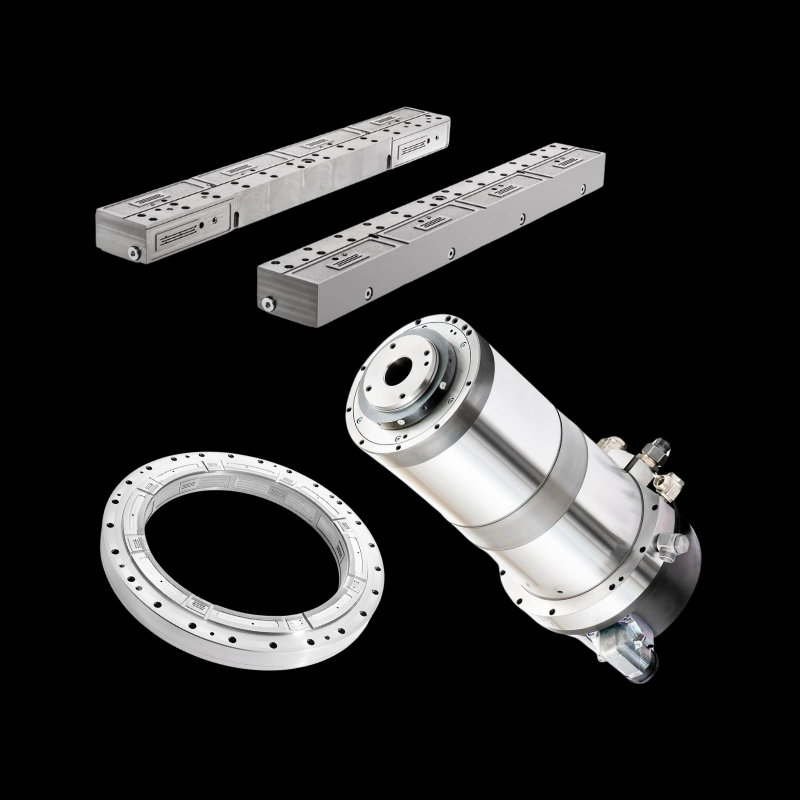

Automation in CNC machining involves integrating automated systems such as robotic arms, automated tool changers, and software solutions to handle tasks without constant human intervention. This can lead to increased efficiency, as machines can operate continuously with minimal downtime.

Automation also enhances precision and repeatability. Automated systems can consistently perform tasks with high accuracy, reducing the margin of error that can occur with manual operations.

However, automation comes with higher upfront costs. Investing in automated systems requires significant capital, which may not be feasible for small businesses or startups. Additionally, there's a learning curve associated with implementing and maintaining these systems. Training your workforce to handle automated equipment and troubleshooting potential issues can take time and resources.

Types of CNC Machining Automation

Here's a look at some few types of CNC machining automation:

- Robotic Arm Integration: Robotic arms are frequently used in CNC machining to handle various tasks such as loading raw materials, unloading finished parts, and transferring workpieces between different machining stations. This reduces manual labor, increases precision, and allows for continuous operation.

- Pallet Systems: Pallet changers streamline the production process by allowing quick swapping of workpieces. While one pallet is being machined, another can be prepared, significantly reducing machine downtime and boosting productivity. This system is ideal for high-mix, low-volume production environments.

- Automatic Loaders: Automatic loaders feed raw materials into the CNC machine without human intervention. This system is particularly beneficial in handling heavy or awkwardly shaped materials, ensuring consistent loading and reducing the risk of operator injury.

- Bar Feeders: Bar feeders are essential for CNC lathes and other machines that work with long, cylindrical materials. They automatically feed bar stock into the machine, allowing for continuous operation and increasing production efficiency. Bar feeders are crucial for high-volume production runs.

- CNC Robots: CNC robots are versatile automation solutions that can perform a variety of tasks within the machining environment. They can load and unload parts, handle secondary operations like deburring, and work in coordination with other automated systems to streamline the entire production process.

What to Automate in CNC Machining

Determining what aspects of your CNC machining operations to automate and the optimal timing for implementing automation can significantly impact your productivity and efficiency. Here are key factors to consider when deciding what and when to automate:

- High-Volume, Repetitive Tasks: Automate tasks that are repetitive and high-volume, as these are prone to human error and can be monotonous for operators. Automated systems can perform these tasks consistently and efficiently, freeing up your workforce for more complex and value-added activities.

- Precision-Dependent Operations: Operations requiring high precision and tight tolerances are ideal candidates for automation. Automated systems can achieve a level of accuracy that is difficult to match manually, reducing errors and waste in high-precision industries such as aerospace, automotive, and medical devices.

- Material Handling: Automating material handling processes, such as loading and unloading raw materials, transferring workpieces, and moving finished products, can streamline your production flow. This reduces manual handling time and minimizes the risk of damage or injury.

- Tool Changes: Automated tool changers (ATCs) are essential for operations involving multiple tool changes. ATCs can quickly switch tools during machining processes without manual intervention, reducing downtime and increasing overall machine utilization.

- Secondary Operations: Tasks such as deburring, cleaning, and inspection can be automated to maintain a consistent quality level and free up manual labor for other important functions. Automated inspection systems, for example, can perform quality checks with high accuracy and speed.

- High-Mix, Low-Volume Production: In a high-mix, low-volume production environment, flexibility is key. Automating processes that can adapt to different products and setups without extensive reconfiguration can save time and increase productivity. Systems like robotic arms and flexible manufacturing cells are ideal for such scenarios.

- Labor-Intensive Processes: Processes that require significant manual labor are excellent candidates for automation. Reducing reliance on manual labor can lower costs, improve safety, and mitigate the risks associated with labor shortages.

- Complex Machining Tasks: Complex tasks that require precise coordination and timing, such as multi-axis machining and simultaneous operations, benefit greatly from automation. Automated systems can execute these tasks with precision and consistency, reducing cycle times and improving product quality.

Pros and Cons of Automating Your New CNC Machine

Automating your new CNC machine can offer numerous benefits, but it also comes with potential drawbacks. Understanding both the pros and cons will help you make an informed decision about whether automation is the right choice for your operations.

Pros of CNC Machine Automation

- Increased Productivity: Automated CNC machines can operate continuously, even outside regular working hours. This leads to higher output and faster turnaround times. Automation minimizes downtime by quickly performing tasks such as tool changes and material handling.

- Enhanced Precision and Consistency: Automated systems reduce the variability associated with manual operations, ensuring each part is produced to exact specifications. This consistency is crucial for industries requiring high precision, such as aerospace and medical manufacturing.

- Reduced Labor Costs: By automating repetitive and labor-intensive tasks, you can lower labor costs. Fewer operators are needed to oversee the production process, allowing you to allocate resources more efficiently.

- Improved Safety: Automation reduces the need for manual intervention in potentially hazardous operations. This minimizes the risk of workplace injuries and enhances overall safety.

- Scalability: Automated systems can be scaled up to meet increased production demands. They offer the flexibility to handle larger volumes without significant changes to the workforce or infrastructure.

- Better Quality Control: Automation can integrate advanced quality control systems that monitor and inspect products in real-time. This ensures that defects are detected and corrected promptly, maintaining high-quality standards.

- Efficient Use of Materials: Automated systems optimize material usage by reducing waste. Precise control over machining processes leads to more efficient cutting and less scrap.

Cons of CNC Machine Automation

- High Initial Costs: The upfront investment for automated CNC machines and associated systems can be substantial. This includes the cost of equipment, installation, and training for your workforce.

- Complexity of Implementation: Integrating automation into your CNC operations requires careful planning and execution. This includes selecting the right systems, training personnel, and setting up maintenance protocols. The complexity can be a barrier for smaller operations.

- Maintenance and Downtime: Automated systems require regular maintenance to ensure optimal performance. If not properly maintained, they can experience downtime, which can disrupt production schedules.

- Dependence on Skilled Technicians: Troubleshooting and maintaining automated systems often require specialized skills. Ensuring you have access to skilled technicians is essential for minimizing downtime and keeping operations running smoothly.

- Potential Job Displacement: While automation reduces labor costs, it can also lead to job displacement. Workers whose roles are automated may need to be retrained or redeployed within the organization.

- Integration Challenges: Ensuring that new automated systems integrate seamlessly with existing machinery and software can be challenging. Compatibility issues can arise, requiring additional investment in software or hardware upgrades.

- Security Concerns: Automated systems often rely on networked software, which can be vulnerable to cyberattacks. Ensuring robust cybersecurity measures are in place is crucial to protect your operations.

Balancing the Pros and Cons

When deciding whether to automate your new CNC machine, consider the following steps:

- Conduct a Cost-Benefit Analysis: Evaluate the potential productivity gains and cost savings against the initial investment and ongoing maintenance costs. A detailed cost-benefit analysis can help you understand the financial implications of automation.

- Assess Your Production Needs: Determine if your current and projected production volumes justify the investment in automation. High-volume, repetitive tasks are often the best candidates for automation.

- Evaluate Workforce Impact: Consider how automation will impact your workforce. Plan for retraining or redeploying employees whose roles may be affected by automation.

- Plan for Integration: Develop a comprehensive plan for integrating automation into your operations. This includes selecting the right systems, training personnel, and establishing maintenance protocols.

- Ensure Cybersecurity: Implement robust cybersecurity measures to protect your automated systems from potential threats.

Automating your new CNC machine can significantly enhance productivity, precision, and efficiency. However, it's essential to weigh these benefits against the potential drawbacks, such as high initial costs and complexity of implementation. By carefully evaluating your needs and planning for integration, you can make an informed decision that aligns with your business goals and maximizes the advantages of CNC automation.

What to Look for in CNC Automation Types

Choosing the right type of automation for your CNC operations involves evaluating several critical factors. These factors ensure that the automation system you select will meet your needs, integrate smoothly with your existing setup, and provide long-term benefits. Here's what to consider:

- Ease of Programming and Operation: Automation systems should be user-friendly and easy to program. Look for intuitive software interfaces and systems that offer simplified programming features. This reduces the learning curve for operators and minimizes the chances of errors during setup.

- Service and Support: Reliable service and support are crucial when investing in automation. Choose brands and vendors known for their excellent customer service, responsive technical support, and comprehensive warranty coverage. This ensures that any issues are promptly addressed, minimizing downtime.

- Mobility and Flexibility: Some automation systems, like robotic arms and loaders, should be easily movable to adapt to changing production needs. Opt for equipment that can be reconfigured or relocated without extensive effort, providing flexibility as your production requirements evolve.

- Software Integration: Ensure that the automation software integrates seamlessly with your existing CNC machine control systems. Compatibility with popular CAD/CAM software and the ability to communicate with other automation systems is essential for creating a cohesive and efficient workflow.

- Installation Process: Consider the complexity and duration of the installation process. Automated systems that are easier and quicker to install can reduce initial setup time and cost. Clear installation guidelines and support from the vendor can facilitate a smoother implementation.

- Brand Reputation: Opt for well-established brands with a strong reputation in the industry. Trusted brands are more likely to provide reliable, high-quality products and better after-sales support. Research customer reviews and case studies to gauge the performance and reliability of different brands.

- Capacity and Scalability: Assess the capacity of the automation system to handle your current production volume and its scalability for future growth. Systems that can easily be expanded or upgraded ensure that your investment remains viable as your business grows.

- Standardization: Standardized automation systems offer compatibility with a wide range of CNC machines and tools. This compatibility simplifies integration and reduces the need for custom modifications. Standard components are also easier to replace and maintain.

- Collaboration Features: Automation systems that facilitate collaboration between different pieces of equipment enhance overall efficiency. Look for features that allow for seamless communication and coordination between robotic arms, loaders, pallet systems, and CNC machines.

Implementing the Right Automation

When selecting and implementing CNC automation, consider these steps to ensure a successful integration:

- Conduct a Needs Assessment: Identify the specific needs of your production process and determine which types of automation will provide the most significant benefits.

- Research and Compare: Evaluate different automation systems based on the factors listed above. Compare features, costs, and user reviews to make an informed decision.

- Plan the Integration: Develop a detailed plan for integrating the chosen automation system into your existing setup. This includes scheduling installation, training operators, and setting up maintenance protocols.

- Test and Optimize: After installation, thoroughly test the automation system to ensure it meets your expectations. Make any necessary adjustments and continuously monitor performance to optimize efficiency.

Selecting the right CNC automation system involves careful consideration of various factors, including ease of programming, service support, mobility, software integration, installation complexity, brand reputation, capacity, standardization, and collaboration features. By evaluating these aspects, you can choose an automation solution that enhances your CNC operations, boosts productivity, and offers long-term value. Automation is a significant investment, and making an informed choice ensures that your production processes remain efficient and competitive.

When You Should Include Automation

- Scaling Production: If your business is experiencing growth and you need to scale production, automation can help meet increased demand without a corresponding rise in labor costs. Automating during this phase ensures you can handle higher volumes efficiently.

- Reducing Bottlenecks: Identify bottlenecks in your production process where manual intervention slows down operations. Automating these stages can streamline workflow and improve overall production speed.

- Enhancing Competitiveness: To stay competitive in the market, adopting the latest automation technologies can give you an edge. Automation can lead to faster turnaround times, higher product quality, and lower production costs, making your business more competitive.

- Responding to Labor Shortages: In times of labor shortages, automation can maintain production levels without increasing workforce size. This is particularly relevant in industries facing skilled labor shortages.

- Improving Safety: Automate hazardous or ergonomically challenging tasks to enhance workplace safety. Automation reduces the risk of injuries associated with repetitive strain, heavy lifting, and exposure to dangerous materials.

Deciding what and when to automate in CNC machining involves evaluating the specific needs of your operations and identifying areas where automation can provide the most significant benefits. By focusing on high-volume, precision-dependent, labor-intensive, and complex tasks, and implementing automation at strategic times, you can enhance productivity, improve product quality, and stay competitive in the market. Automation is not a one-size-fits-all solution, but with careful planning and execution, it can transform your CNC machining processes and drive long-term success.