Embarking on a journey into the CNC industry can be daunting, especially for first-time buyers and machinists. But fear not! With the right guidance and an understanding of the essential tools and equipment, you're well on your way to setting up a successful CNC shop.

For first-time CNC buyers and machinists, setting up a CNC business requires a comprehensive starter kit. This kit should include key machinery like CNC milling machines and lathes, essential software for CAD and CAM, quality cutting tools, measurement instruments for precision, a reliable computer system, safety equipment, material handling tools, and maintenance supplies. Additionally, investing in training and resource materials is crucial for ongoing success.

As you delve deeper into the essentials of a CNC business, you'll uncover insights and tips that will not only streamline your initial setup but also pave the way for long-term success in this exciting field.

The cornerstone of any CNC business is its machinery. Here's what you'll need:

- CNC Milling Machines and Lathes: These are the workhorses of any CNC shop. Consider the size and type of projects you plan to undertake when selecting machines. Options range from smaller desktop models to large industrial machines.

- Quality Cutting Tools: Invest in a variety of cutting tools, including end mills, drills, and lathe tools. The quality of these tools directly impacts the precision and quality of your work.

- Measurement Instruments: Precision is key in CNC machining. Calipers, micrometers, and dial indicators are essential for accurate measurements.

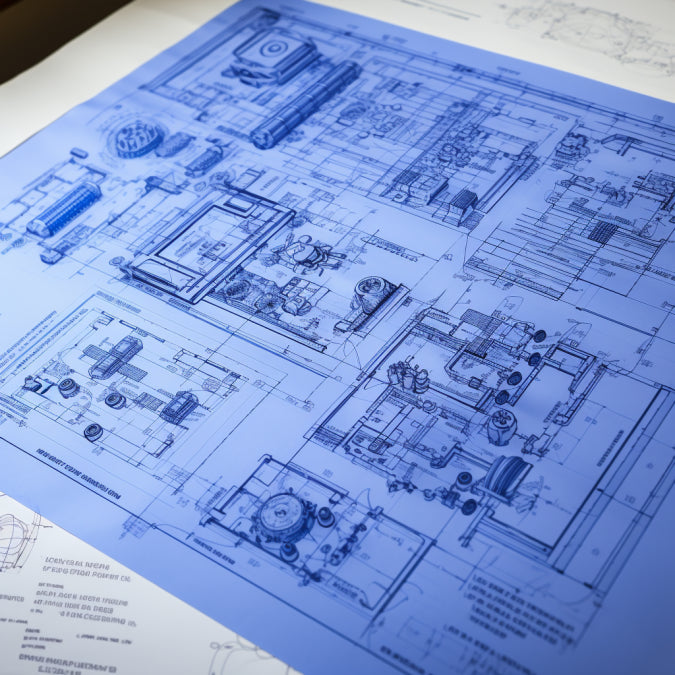

- CAD and CAM Software: Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are vital for designing and translating your projects into machine-readable formats.

- Computer System: A robust computer system capable of running CAD and CAM software smoothly is a must-have.

- Safety Equipment: Never compromise on safety. Ensure you have safety glasses, gloves, ear protection, and other necessary safety gear.

- Material Handling Tools: Equipment such as lifting devices, pallet jacks, and storage solutions will help in efficiently managing materials.

- Maintenance Supplies: Regular maintenance is crucial for the longevity of your machinery. Keep an inventory of lubricants, cleaning supplies, and spare parts.

- Training and Resource Materials: Last but not least, invest in training and resources. This could include manuals, online courses, or workshops to enhance your skills and knowledge.

Starting a CNC business is more than just purchasing equipment. It's about understanding your machinery, mastering the software, and consistently honing your skills.

When selecting CNC machinery, consider the following:

- Your Project Needs: Assess the type of work you plan to do. This will influence the size and capabilities of the machines you need.

- Budget Considerations: Balance the cost with the quality and features of the machinery. Sometimes, a higher initial investment can save money in the long run.

- Space Requirements: Make sure you have enough space for the machinery, considering both its footprint and operational space.

- Support and Warranty: Look for manufacturers who offer good customer support and warranties.

CAD and CAM software are central to CNC machining. Here’s how to master them:

- Choose User-Friendly Software: If you're a beginner, start with software that's known for its ease of use.

- Practice Regularly: The more you use the software, the more proficient you'll become.

- Seek Resources and Training: Utilize online tutorials, forums, and courses to enhance your skills.

Effective management of materials and tools is crucial for efficiency:

- Organize Your Workspace: Keep your tools and materials well-organized for easy access and inventory management.

- Implement a Maintenance Schedule: Regular maintenance prevents unexpected downtime and extends the life of your tools and machines.

- Invest in Quality Tools: High-quality tools may be more expensive upfront but can provide better performance and longevity.

Safety and training should never be overlooked:

- Implement Safety Protocols: Establish and enforce safety rules in your shop.

- Invest in Training: Continuous learning is key. Attend workshops, webinars, and training sessions to stay updated with the latest CNC technologies and techniques.

- Encourage a Culture of Safety: Make safety a part of your shop’s culture, ensuring that every team member understands and adheres to safety practices.Safety and training should never be overlooked:

- Implement Safety Protocols: Your CNC shop must have clear, strict safety rules. This includes proper use of machinery, handling of tools, and emergency procedures. Regular safety drills and updates on protocols can significantly reduce workplace accidents.

- Invest in Training: The CNC field is continuously evolving, with new techniques and technologies emerging regularly. To stay competitive and proficient, invest in ongoing training. This can include in-house training sessions, online courses, industry workshops, and webinars. Such continuous learning not only enhances skills but also introduces new perspectives and methodologies in CNC machining.

- Encourage a Culture of Safety: Safety shouldn't just be a rule; it should be an integral part of your shop's culture. This means every team member, from the newest apprentice to the most experienced machinist, should understand, respect, and adhere to safety practices. Regular discussions, open forums on safety concerns, and incentivizing safe practices can help in cultivating this culture. Remember, a safe environment is not only about preventing accidents but also about creating a space where everyone feels responsible for each other's well-being.

Starting a CNC business is a thrilling venture that combines technology, creativity, and precision. By focusing on the essential machinery and equipment, selecting the right tools, mastering software, managing materials effectively, and prioritizing safety and training, you set a solid foundation for success. Remember, the key to a prosperous CNC shop lies in meticulous planning, continual learning, and an unwavering commitment to quality and safety. Embrace these principles and watch your CNC business thrive.

Summary:

- Safety Protocols: Implement and update regularly.

- Ongoing Training: Invest in workshops, webinars, and courses.

- Culture of Safety: Make safety a core part of your shop’s ethos.

- Meticulous Planning: Essential for efficient operations.

- Continual Learning: Keeps you updated and competitive.

- Commitment to Quality: Focus on precision and excellence.

- Solid Foundation: Built on right tools, skills, and practices.

- Business Success: Follows from a focus on planning, safety, and quality.

This comprehensive approach ensures not only a successful launch of your CNC business but also its sustained growth and relevance in a rapidly evolving industry.