When it comes to CNC machining, the size of the machine, as well as the size of the parts it produces, plays an important role in determining both the capabilities and limitations of what can be achieved.

In CNC machining, size indeed matters. It affects not only the choice of machinery but also the design, efficiency, and cost of production. By understanding and adapting to these size-related considerations, manufacturers can optimize their CNC machining processes to meet diverse project requirements effectively. Through strategic design and machine selection, the challenges posed by size constraints can be successfully navigated to achieve high-quality, cost-effective manufacturing outcomes.

Machine Size: A Determining Factor

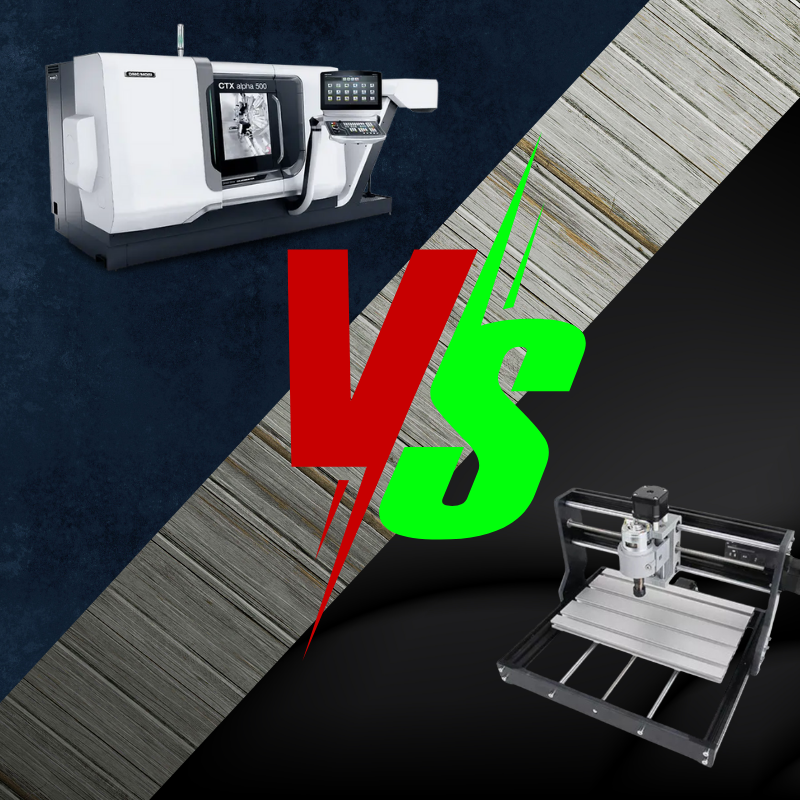

The size of a CNC machine directly influences the scale of work it can handle. Larger machines are equipped to manage bigger, heavier workpieces, making them suitable for industrial-scale production where large components are common. Conversely, smaller machines, often found in educational settings, hobbyist workshops, or small businesses, are designed for precision work on a smaller scale.

What part of the machine takes more of the size?

In CNC machines, the part that takes up the most space can vary depending on the type of CNC machine in question (e.g., lathe, milling machine, router). However, some components significantly contribute to the overall size and space requirements of these machines.

For CNC mills and lathes, the bed and the driving system are among the primary contributors to the machine's overall size. The bed is where the raw material or workpiece is mounted, and its size dictates the maximum size of the workpiece that can be accommodated. This component must provide a stable and precise platform for operations, often featuring mechanisms for securing the workpiece in place, such as t-slots or holes for jigs. For more advanced machines, such as 5-axis CNC machines, the bed may also include rotational capabilities, further impacting the machine's size and complexity.

The driving system, comprising motors that move the tool along various axes, also plays a significant role in the machine's size. This system includes components like servo motors, ball screws, and linear guides, which work together to ensure precise movement and positioning of the cutting tool or workpiece. The complexity and robustness of the driving system, needed to achieve the desired precision and speed, can significantly impact the overall machine size.

For CNC routers, the frame is a critical factor in the machine's size. The frame supports the machine and provides the rigidity needed to resist cutting forces. Larger routers may have a stand with legs or a welded base, while smaller models might sit atop a bench. Materials for frames vary from aluminum extrusions to steel weldments, influencing the machine's footprint.

Impact on Part Size and Design

The maximum part size a CNC machine can handle is limited by its work envelope - the physical space within which the machine can operate. This means the dimensions of the material that can be worked on are confined to the size of the machine's table and its range of motion. Designing parts for CNC machining requires consideration of these constraints to ensure the part can be manufactured within a single setup, thereby optimizing production efficiency and minimizing costs.

Choosing the Right CNC Machine Size for Your Needs

Deciding on the correct CNC machine size can significantly impact your project's success. Selecting the appropriate CNC machine size involves considering the material size you intend to work with, the space available in your workshop, and the complexity of the projects you plan to undertake. Larger machines offer greater versatility and capacity for complex or large-scale projects, while smaller machines are suitable for detailed work in limited spaces.

Understanding CNC Machine Size Categories

Understanding the categories—small, medium, large, and extra-large—helps in identifying which machine fits your specific project requirements, taking into account the material size, precision needed, and the physical space available in your workshop.

When comparing CNC machine sizes, consider:

- The maximum material size you plan to work with.

- The complexity and precision required for your projects.

- The available space in your workshop or industrial setting.

- Future project scalability and potential need for larger capacity.

- Budget constraints and cost-effectiveness of the machine size.

When it comes to CNC machining, the size of the machine is often categorized by the working area it can accommodate, which directly correlates with the size of the material or part it can handle. Categorizing helps a lot, although specific dimensions for small, medium, large, and extra-large CNC machines can vary widely depending on the manufacturer, the type of machine and its intended use.

It's important to consider the specific requirements of your projects, including the size of the parts you intend to machine, the materials you will be working with, and the space available in your facility when choosing a CNC machine.

Choosing a Small CNC Machine: What You Need to Know"

Small CNC machines are renowned for their affordability, footprint, and suitability for beginners and small-scale projects. They offer precision and flexibility within a compact design, ideal for limited spaces. However, their size may limit the scope of work they can handle, affecting the size of materials and the complexity of tasks they can undertake.

Small CNC machines, often desktop or benchtop models, are designed for precision milling, drilling, and cutting on a smaller scale. They are perfect for hobbyists, educators, and small businesses that require detail-oriented work without the need for large, industrial-size equipment. Despite their compact size, these machines can be surprisingly powerful and versatile, capable of working with a variety of materials including plastics, wood, and metals.

Choosing a Medium-Sized CNC Machine: What You Need to Know"

Medium-sized CNC machines strike a balance between the flexibility of smaller units and the power of industrial models. They are ideal for a wide range of applications, offering more working space and capabilities than smaller machines, without requiring the significant investment and space needed for larger equipment.

Medium-sized CNC machines are characterized by their versatility, making them suitable for both small businesses and serious hobbyists. These machines often come with a more robust set of features compared to their smaller counterparts, including larger working areas, higher power outputs, and advanced control systems. They can handle a broader range of materials with greater precision and efficiency, making them a popular choice for those looking to expand their capabilities without moving into the realm of large, industrial machines.

Choosing a Large-Sized CNC Machine: What You Need to Know"

Large-sized CNC machines are designed for high-volume, industrial applications, offering unparalleled precision and capacity. They require substantial space and investment but provide the efficiency and versatility needed for complex, large-scale projects. Key considerations include workspace dimensions, power requirements, and long-term production goals.

Large CNC machines are the backbone of heavy industry, capable of handling extensive manufacturing processes with precision and speed. These machines are ideal for machining large parts or handling bulk production runs efficiently. When selecting a large CNC machine, it's important to consider the machine's size, power, and the technology that drives its performance. Advanced features like multi-axis capabilities, high-speed spindles, and automated tool changers can significantly enhance productivity and flexibility.

Choosing an Extra-Large CNC Machine: What You Need to Know

Extra-large CNC machines are designed for high-volume production and handling large-scale projects with ease. They require substantial space and investment but offer unparalleled precision, speed, and flexibility in manufacturing large parts or running extended production cycles.

Extra-large CNC machines cater to industries requiring large part fabrication, such as aerospace, automotive, and shipbuilding. These machines provide extensive work envelopes, powerful cutting abilities, and the robustness needed for heavy-duty machining. They can efficiently process a wide range of materials, from metals to composites, ensuring precision and quality over large surface areas. Understanding the specific capabilities of these machines is essential for aligning your project requirements with the right equipment.

Efficiency and Cost Implications

Larger CNC machines, while capable of handling bigger projects, come with higher operational costs, including increased power consumption and the need for larger spaces to house them. These factors can significantly impact the cost-efficiency of manufacturing, especially for smaller-scale operations. On the other hand, smaller machines may offer reduced operational costs but at the expense of the size and complexity of parts they can produce.

Design Considerations for Minimizing Machine Size Impact

To mitigate the limitations imposed by machine size, designers can employ several strategies:

- Optimize part design to accommodate the capabilities of available machines, such as adjusting part dimensions or splitting larger parts into smaller segments that can be machined separately and assembled later.

- Utilize multi-axis machines that offer greater flexibility in manufacturing complex parts within compact dimensions.

- Apply design for manufacturability (DFM) principles to streamline the manufacturing process, reduce the need for specialized tooling, and minimize machine setups.