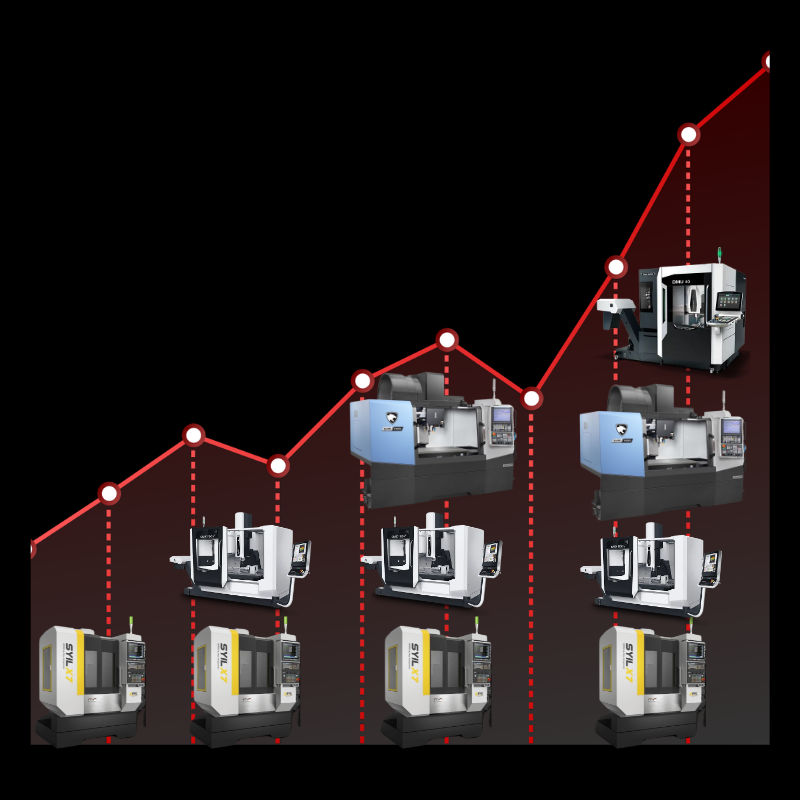

In the quest for operational efficiency and market competitiveness, investing in a new CNC machine is a significant decision that should closely align with your overall business strategy. This article delves into the strategic considerations of such an investment, helping you evaluate whether a new CNC machine is not just a desirable addition but a strategic fit for your business's long-term goals.

Aligning a new CNC machine purchase with your business strategy involves evaluating the investment's role in achieving operational efficiencies, market expansion, and technological advancements. It should support your strategic objectives, such as increasing production capacity, entering new markets, or enhancing product quality, thereby ensuring the investment contributes to sustainable business growth.

Discover the critical factors to consider when aligning a CNC machine purchase with your business strategy.

Assessing Strategic Fit

The first step in ensuring a new CNC machine purchase aligns with your business strategy is to conduct a thorough assessment of how the machine fits into your current operations and future goals. This includes:

- Evaluating Production Needs: Does the new machine meet a current capacity gap or enable the production of new products?

- Technological Advancements: Will the investment bring your operations up to speed with the latest technological standards, improving efficiency and product quality?

- Market Opportunities: Can the new machine help you tap into new markets or better serve existing ones?

Conduct a SWOT analysis (Strengths, Weaknesses, Opportunities, Threats) to understand how the CNC machine fits into your strategic plan. Review your business plan and long-term goals to ensure the investment is in line with your growth trajectory.

Financial Considerations and ROI

A strategic investment in a new CNC machine must also make financial sense. Analyzing the return on investment (ROI) and how the purchase impacts your financial planning is crucial. Key considerations include:

- Cost vs. Benefit Analysis: Evaluate the upfront costs against the expected benefits, such as increased efficiency, cost savings, and potential revenue growth.

- Cash Flow Impact: Consider how the investment affects your cash flow and whether your business can sustain the expenditure without compromising other strategic initiatives.

- Financing Options: Explore financing options that align with your financial strategy, minimizing the impact on operational funds.

Use financial modeling to project the long-term financial impact of the CNC machine purchase. Then consider leasing or financing arrangements to mitigate the immediate financial burden. Align the investment with fiscal periods where the impact on cash flow is manageable.

Future-Proofing Your Operations

Investing in a new CNC machine is also about future-proofing your operations. It's essential to consider:

- Scalability: Will the new machine grow with your business, or will it become obsolete as your needs evolve?

- Flexibility: Does the machine offer the versatility needed to adapt to changing production demands or market trends?

- Innovation Edge: Can the technology provide you with a competitive advantage in innovation, quality, or production speed?

Look for modular or upgradable machines that can adapt to future needs. Evaluate the supplier's commitment to innovation and their track record for supporting customer’s post-purchase. Consider the role of automation and data analytics in enhancing operational efficiency and decision-making.